器/1.jpg)

Thin Film Evaporator

International famous film evaporator professional manufacturing enterprise

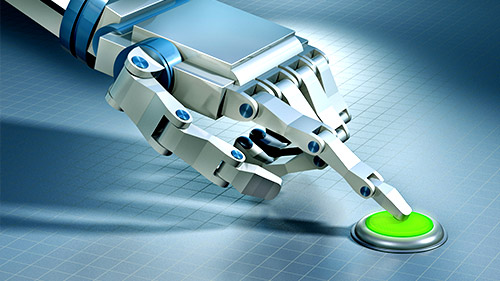

GXZ high-efficient rotary thin film evaporator is a kind of equipment conducting the separation based on the volatility of different materials, with high evaporation intensity and high effectiveness of separation. It is widely used for evaporation, condensation, desolventization, purificaiton, stripping, degasification and deodorzation in petrochemical, fine chemical, pesticide, food, pharmaceutical, and biological chemical industries. In recent years, the thin film evaporator area over 60 square, which are characterized product of our company, have been widely used in the relevant industries and praised by users.

器/1.jpg) large thin film evaporator ready for shipment

large thin film evaporator ready for shipment器/2.jpg) Large thin film evaporator (Stainless steel half-pipe jacket)

Large thin film evaporator (Stainless steel half-pipe jacket)器/3.jpg) Pre-delivery test run of large thin film evaporator (H=26m)

Pre-delivery test run of large thin film evaporator (H=26m)器/4.jpg) Thin film evaporator

Thin film evaporator器/5.jpg) Thin film evaporators at the user’s site (nonyl phenol)

Thin film evaporators at the user’s site (nonyl phenol)器/6.jpg) Thin film evaporators at the user’s site (phospholipid)

Thin film evaporators at the user’s site (phospholipid)器/7.jpg) The cylinder and rotor of thin film evaporator being assembled

The cylinder and rotor of thin film evaporator being assembled器/8.jpg) 50平方米薄膜蒸發(fā)器在用戶現(xiàn)場(chǎng)

50平方米薄膜蒸發(fā)器在用戶現(xiàn)場(chǎng)器/9.jpg) 待發(fā)貨的薄膜蒸發(fā)器

待發(fā)貨的薄膜蒸發(fā)器Product Features

High heat transfer coefficient, short dwell time, low evaporation temperature, great operating flexibility.

Double- end mechanical seal, maintain the vacuum degree.

Inside surface of evaporator is polished to provide a smooth finish.

Demister can prevent the entrainment of gas and liquid.

Distributor can throw materials to the cylinder wall uniformly.

Double- end mechanical seal, maintain the vacuum degree.

Inside surface of evaporator is polished to provide a smooth finish.

Demister can prevent the entrainment of gas and liquid.

Distributor can throw materials to the cylinder wall uniformly.

Technical Parameters

Evaporator surface area (m2): 0.5, 2, 4, 6, 8, 10, 15, 20, 25, 30, 40, 50, 60, 80, 100.

We can provide the special design to your working conditions. Respect the final drawings for all dimensions and weight.

We can provide the special design to your working conditions. Respect the final drawings for all dimensions and weight.